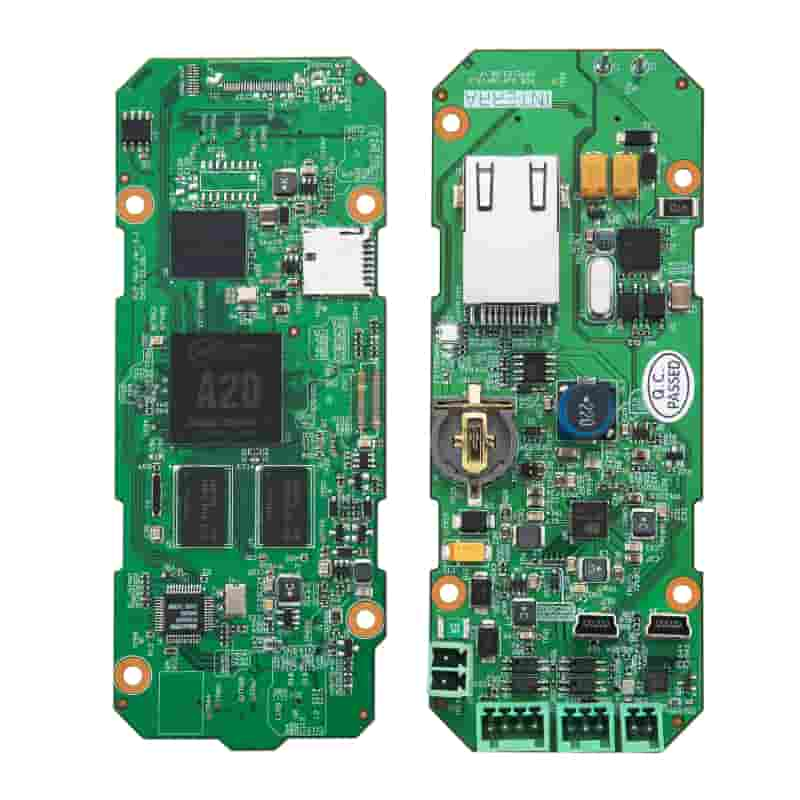

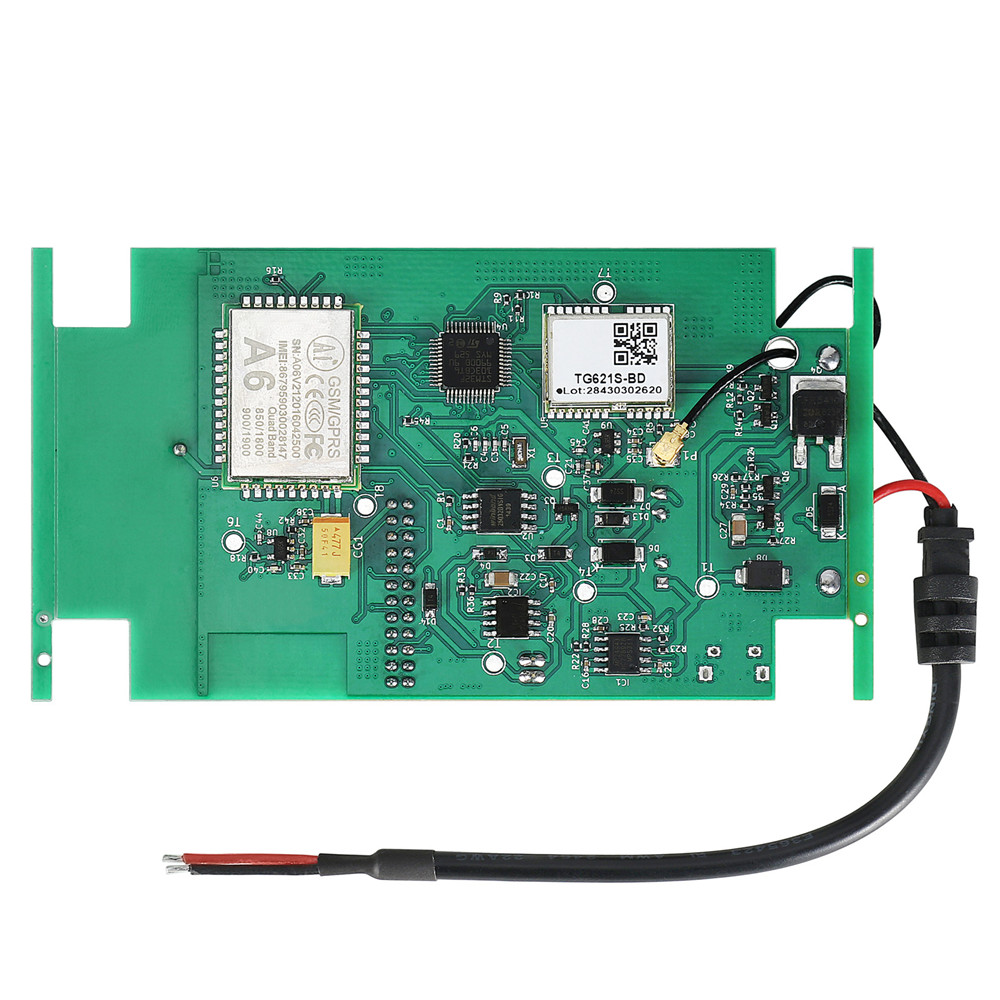

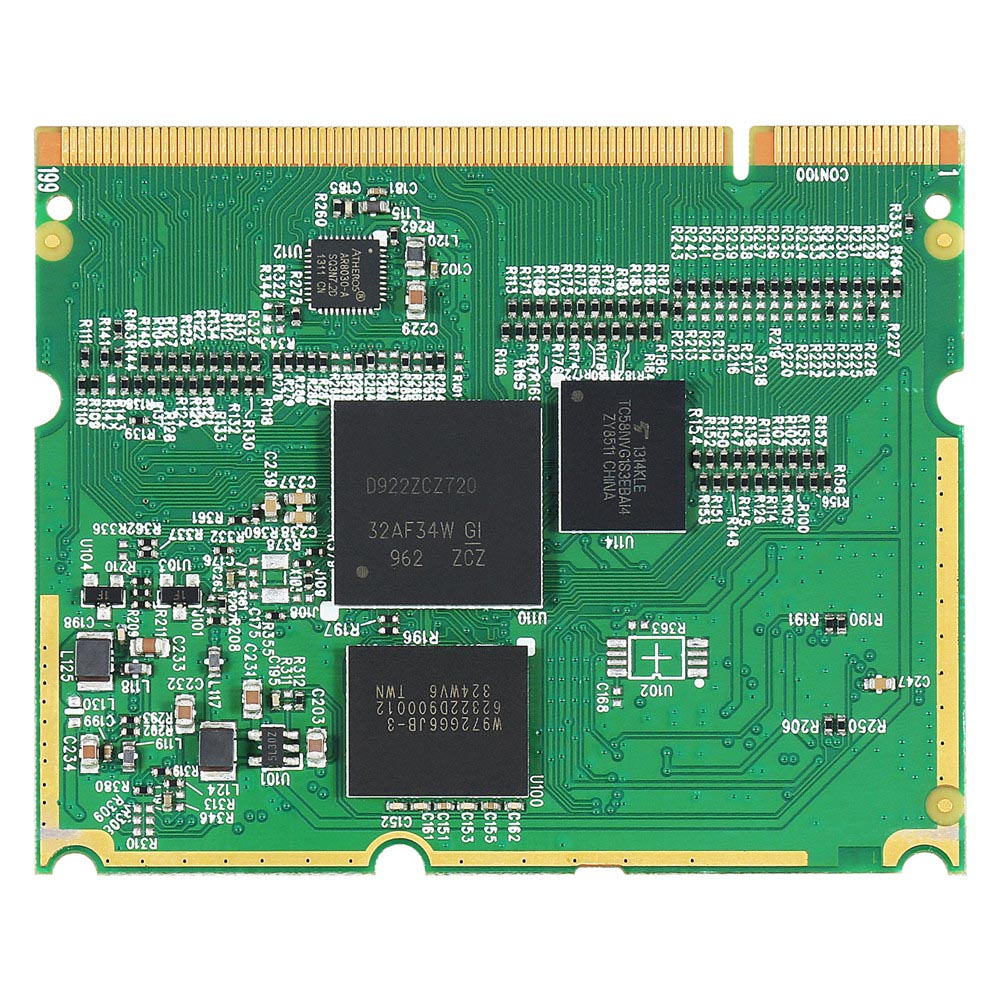

Automotive electronics PCBA board

Sebopeho sa lihlahisoa

● -Teko ea ho tšepahala

● -Traceability

● -Tsamaiso ea mocheso

● -Koporo e boima ≥ 105um

● -HDI

● -Semi - flex

● -E thata - e tenyetseha

● -Mohaho oa microwave o phahameng oa maqhubu

Litšobotsi tsa sebopeho sa PCB

1. Dielectric layer (Dielectric): E sebelisetsoa ho boloka ho pata pakeng tsa mela le lihlopha, tse tsejoang e le substrate.

2. Silkscreen (Legend/Marking/Silkscreen): Ena ke karolo e seng ya bohlokwa.Mosebetsi oa eona o ka sehloohong ke ho tšoaea lebitso le lebokose la boemo ba karolo e 'ngoe le e' ngoe holim'a boto ea potoloho, e loketseng bakeng sa tlhokomelo le boitsebiso ka mor'a kopano.

3.Surface treatment (SurtaceFinish): Kaha bokaholimo ba koporo bo na le oxidized habonolo tikolohong e tloaelehileng, e ke ke ea kenngoa ka tinned (mafutsana solderability), kahoo bokaholimo ba koporo bo tla sireletsoa.Mekhoa ea ts'ireletso e kenyelletsa HASL, ENIG, Immersion Silver, Immersion TIn, le organic solder preservative (OSP).Mokhoa o mong le o mong o na le melemo le mefokolo ea oona, ka kakaretso o bitsoa phekolo ea holim'a metsi.

Bokhoni ba Boenjiniere ba PCB

| Mekhahlelo | Tlhahiso e kholo: 2 ~ 58 layers / Pilot run: 64 layers |

| Max.Botenya | Tlhahiso e kholo: 394mil (10mm) / Pilot run: 17.5mm |

| Lintho tse bonahalang | FR-4 (Standard FR4, Mid-Tg FR4,Hi-Tg FR4, Lead free assembly material) , Halogen-Free, Ceramic e tlatsitsoeng, Teflon, Polyimide, BT, PPO, PPE, Hybrid, Partial hybrid, joalo-joalo. |

| Min.Bophara/ Sebaka | Lera le ka hare: 3mil/3mil (HOZ), Lera ka ntle: 4mil/4mil(1OZ) |

| Max.Botenya ba Koporo | Setifikeiti sa UL: 6.0 OZ / Pilot run: 12OZ |

| Min.Boholo ba lesoba | Boro ea mochini: 8mil(0.2mm) Laser ea cheka: 3mil(0.075mm) |

| Max.Boholo ba Panel | 1150mm × 560mm |

| Aspect ratio | 18:1 |

| Surface Finish | HASL,Khauta e qoelisoang, Tin ea ho qoelisoa, OSP, ENIG + OSP, Silivera e qoelisoang, ENEPIG, Monoana oa Khauta |

| Mokhoa o Khethehileng | Lesoba le Epetsoeng, Sekoti se Foufetseng, Khanyetso e Kenyelelitsoeng, Bokhoni bo Kenyelelitsoeng, Hybrid, Lebasetere la Karolo, Boima bo phahameng bo sa Lekaneng, Ho cheka ka morao, le Resistance control. |

Liboto tsa rona tsa likoloi tsa elektroniki tsa PCBA ke sehlahisoa sa phetoho se etselitsoeng ho fihlela litlhoko tse phahameng tsa indasteri ea likoloi.Joaloka e mong oa bahlahisi ba ka sehloohong ba likoloi tsa PCB, re bokelletse boiphihlelo bo bongata ts'ebetsong ea taolo ea tlhahiso le theknoloji ho netefatsa boleng bo phahameng ka ho fetisisa le ts'epahalo ho bareki ba rona.

Lihlahisoa tsa rona tsa likoloi li fapane ka ho fetisisa 'me li kenyelletsa Heavy Copper Board, HDI (High Density Interconnect), Maqhubu a Phahameng a Phahameng le a Lebelo le Lebelo le Phahameng.Liboto tsena li etselitsoe tlhahiso ea motsamao o hokahantsoeng, motsamao o ikemetseng le motsamao o ntseng o eketseha oa motlakase oa koloi.

Ka tsoelo-pele e potlakileng ea theknoloji ea likoloi, ho na le tlhokahalo e ntseng e eketseha ea lisebelisoa tsa elektroniki tse khonang ho mamella bophelo bo bolelele, moroalo o phahameng oa mocheso le meralo e ntle ea molumo.Liboto tsa rona tsa likoloi tsa PCBA li etselitsoe ka ho khetheha ho fihlela litlhoko tsena, ho fana ka ts'ebetso e phahameng le ho ts'epahala maemong a thata a likoloi.

E 'ngoe ea likarolo tsa bohlokoa tsa mapolanka a rona a PCBA ke bokhoni ba ho sebetsana le koporo e teteaneng, e leng ea bohlokoa bakeng sa likopo tse hlokang bokhoni bo phahameng ba hona joale le matla a ho fetisa matla.Sena se etsa hore liboto tsa rona e be tse loketseng likoloi tsa motlakase le tse nyalisitsoeng moo taolo ea matla e leng bohlokoa.

Ho feta moo, theknoloji ea rona ea HDI e etsa bonnete ba hore boto e na le moralo o kopaneng le sekhahla se phahameng sa potoloho, e leng se etsang hore e be se loketseng lits'ebetso tse hlokang sebopeho se senyenyane.Sena se lumella baetsi ba likoloi ho rala litsamaiso tse boreleli le tse kopaneng ntle le ho beha ts'ebetso kotsing.

Ho feta moo, meralo ea rona ea boto ea maqhubu a holimo le ea lebelo le holimo e thusa ho kopanya ka mokhoa o se nang moeli oa mesebetsi e tsoetseng pele joalo ka sistimi ea radar, mesebetsi ea ho khanna e ikemetseng, le litsamaiso tse tsoetseng pele tsa lithuso tsa bakhanni (ADAS).Liboto tsena li fana ka botšepehi bo botle ba matšoao, ho netefatsa phetiso e nepahetseng le e tšepahalang ea data ka nako ea nnete.

Khamphaning ea rona, re etelletsa pele khotsofalo ea bareki mme re loanela ho feta litebello ka ho fana ka lihlahisoa tsa boemo ba pele tse fihlelang maemo a holimo a indasteri.Liboto tsa rona tsa likoloi tsa elektroniki tsa PCBA ha li mokhelo, li fana ka boleng bo holimo, bots'epehi, le ts'ebetso bakeng sa lits'ebetso tsa hau tsa likoloi.

Ka kakaretso, liboto tsa rona tsa likoloi tsa elektroniki tsa PCBA ke tharollo e phethahetseng bakeng sa baetsi ba likoloi ba batlang ho ntlafatsa lisebelisoa tsa bona tsa elektroniki tsa likoloi.Ka boiphihlelo ba rona bo pharaletseng, linyehelo tse fapaneng tsa lihlahisoa, le boitlamo ba boleng, re na le ts'epo ea hore boto ea rona e tla kopana le ho feta litebello tsa hau.Re tšepe hore re tla u fa litheknoloji tse tsoetseng pele bakeng sa bokamoso ba ho tsamaea.